I-Semi Automatic Concrete Block Production Line

--Iimbonakalo--

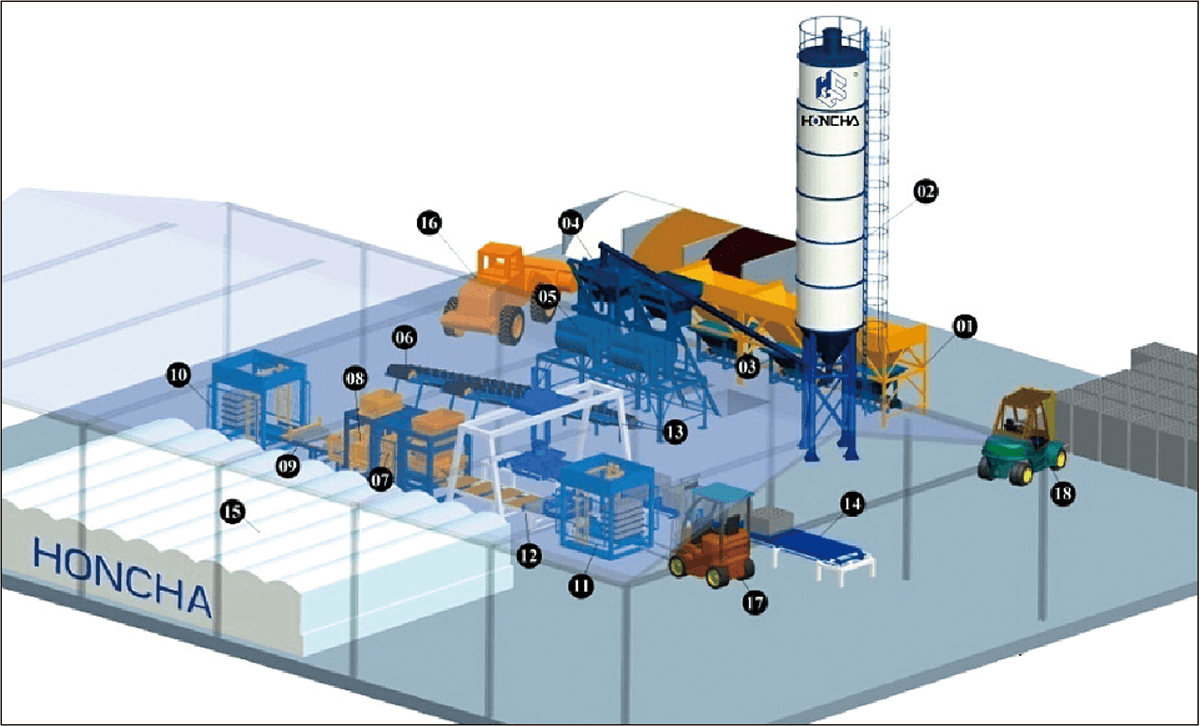

Umgca ozenzekelayo we-Semi: umlayishi wevili uya kubeka ii-aggregates ezahlukeneyo kwi-Batching Station, iya kuzilinganisa kubunzima obufunekayo kwaye emva koko udibanise nesamente kwi-silo yesamente. Zonke izixhobo ziya kuthunyelwa kumxube. Emva kokuxuba ngokulinganayo, umqhubi webhanti uya kuhambisa izinto kwi-Block Making Machine. Iibhloko ezigqityiweyo ziya kudluliselwa kwi-Automatic Stacker. Emva koko ukunyuswa kwefolokhwe kuya kuthatha zonke iipalethi zeebhloko kwigumbi lokunyanga ukunyanga. Kwaye i-pallet tumbler inokukhupha iipalethi nganye nganye kwaye emva koko i-Automatic cuber iya kuthatha iibhloko kwaye ibeke kwimfumba, emva koko i-clamp yefolokhwe inokuthatha iibhloko ezigqityiweyo ukuya eyadini ukuze zithengiswe.

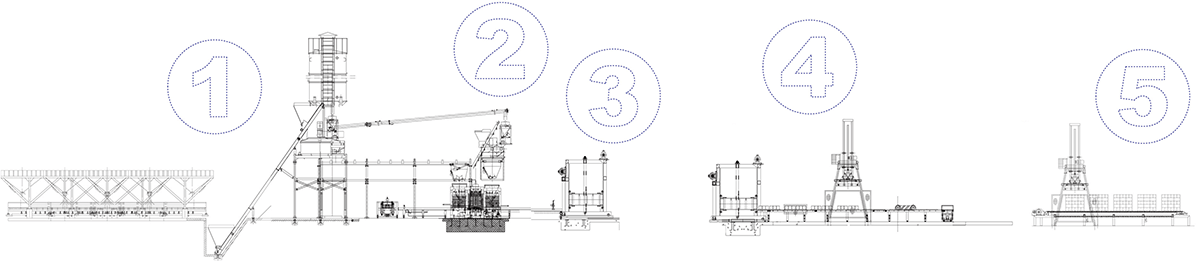

——Icandelo——

1 I-Batching kunye neSityalo sokuxuba

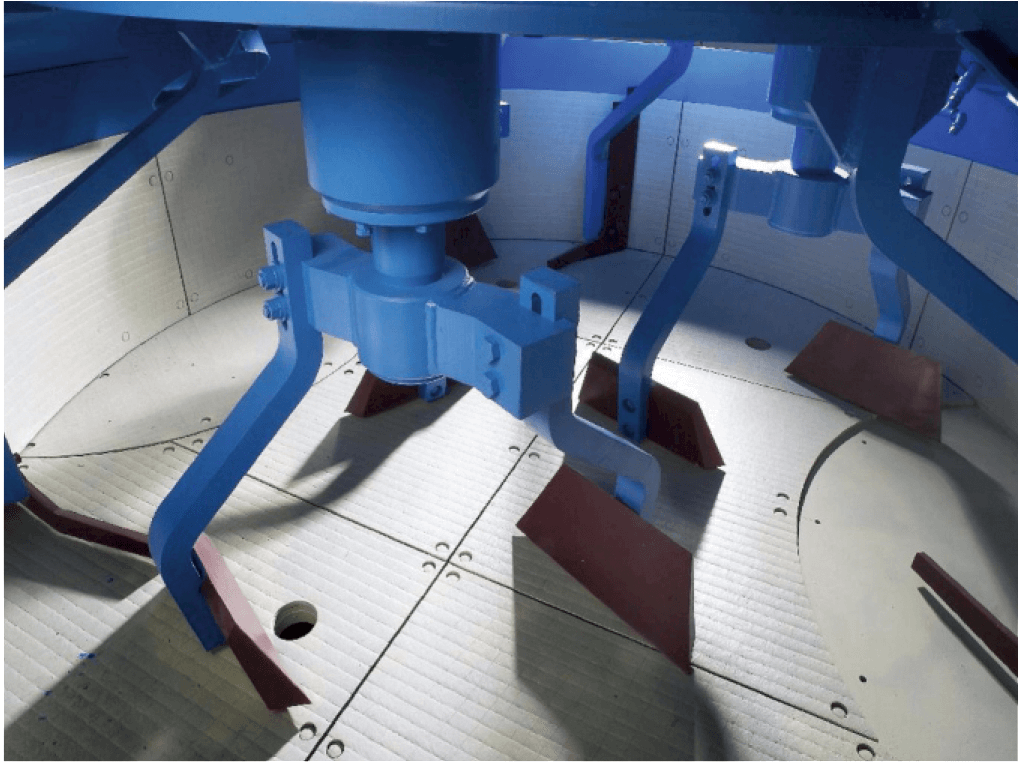

Inkqubo yokudibanisa kunye nokuxuba iqulethe isikhululo sokudibanisa i-multi-component esilinganisa ngokuzenzekelayo kwaye sihambise i-aggregate kumxube onyanzelekileyo. I-samente ithuthwa ukusuka kwisisele sesamente kusetyenziswa i-screw conveyor kwaye ilinganiswe ngokuzenzekelayo kumxube. Nje ukuba umxubi egqibe umjikelo wakhe ikhonkrithi iya kuthuthwa kusetyenziswa inkqubo yethu yokutsiba phezulu ukuya kwisistim yomatshini webhloko ezenzekelayo.

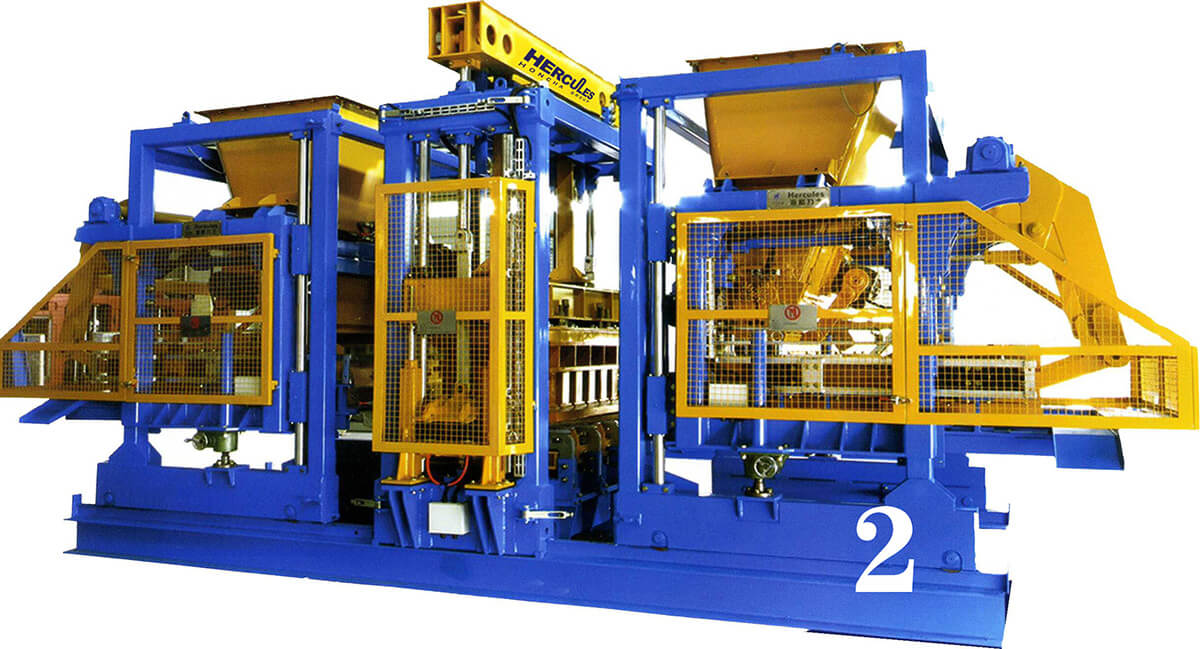

2, umatshini wokuvala

Ikhonkrithi ityhalelwa endaweni yayo ngebhokisi yesondlo kwaye isasazwe ngokulinganayo kumngundo ongezantsi wabasetyhini. Umngundo oyindoda ophezulu ufakwa kumngundo ongezantsi kunye nokusetyenziswa kwentshukumo yetafile ehambelanayo ukusuka kuzo zombini iimbumba ukubumba ikhonkrithi kwibhloko efunwayo. Umatshini unokuba necandelo lokuxuba ubuso obuzenzekelayo ngokupheleleyo bongezwa ukuvumela ukuveliswa kweepavers ezinemibala.

Iimodeli ezikhethiweyo zoomatshini bebhloko: Hercules M, Hercules L, Hercules XL.

3,Stacker

Iibhloko ezitsha ziyacocwa ukuze kuqinisekiswe ukuba zonke zinobude obufanayo kwaye emva koko zihanjiswe kwi-stacker. Emva koko ukunyuswa kwefolokhwe kuya kuthatha zonke iipalethi zeebhloko kwigumbi lokunyanga ukunyanga.

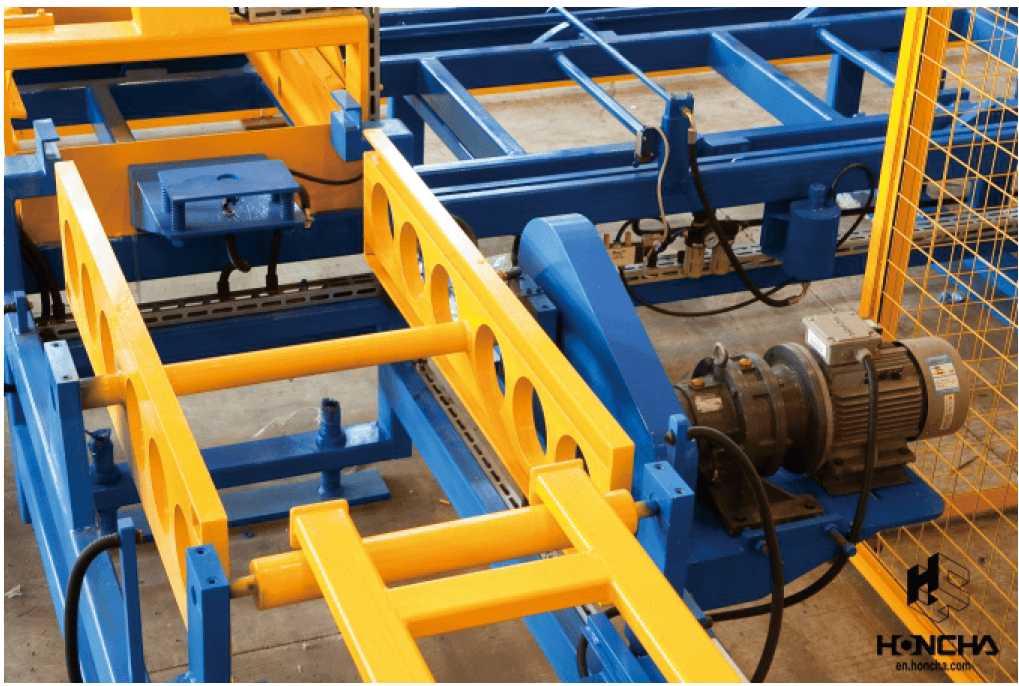

4,Un-stacker

Xa iipaliti zilayishwe ngokupheleleyo kwi-un-stacker ilayishwa ngokuzenzekelayo kwi-pallet yokubuyisela inkqubo kwaye ilungelelaniswe ilungele inkqubo ye-cubing.

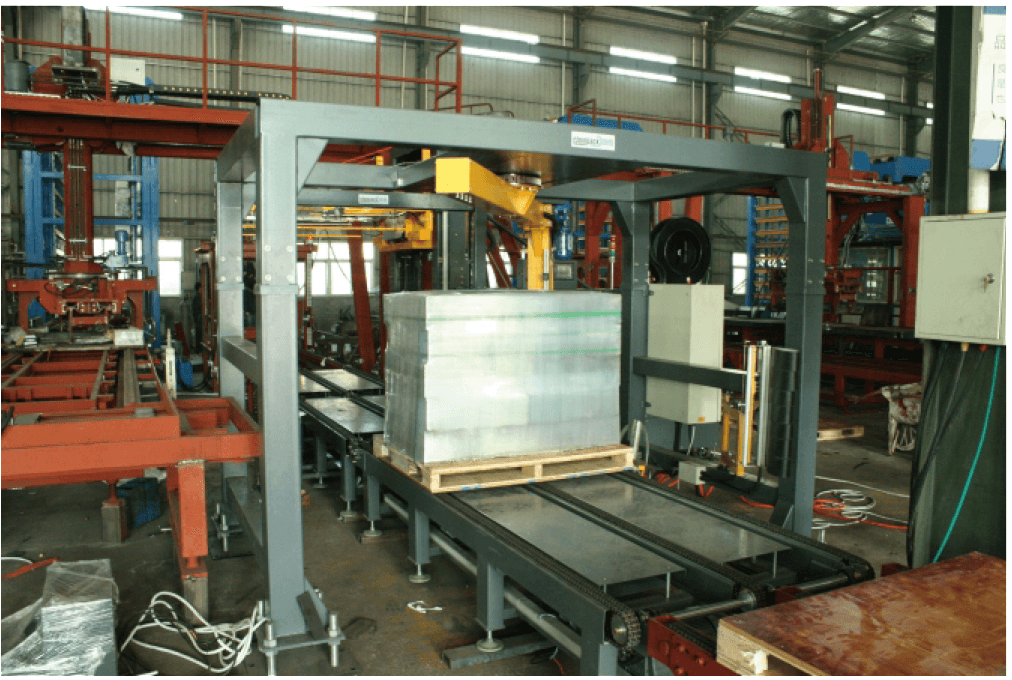

5,Automatic Gantry Type Block Cubing System

Inkqubo ye-cubing iya kuqokelela iibhloko okanye iipali kwiipalethi ezimbini ngexesha kwaye zinqumle kwi-conveyor yokuphuma. Ixhotyiswe ngeengalo ezibambezelayo ezine zerabha ezigqunyiweyo kwaye zisebenza ngoxinzelelo lwegazi kunye nentshukumo ethe tyaba engama-360.

——Semi Automatic Production Line——

| I-Semi Automatic Concrete Block Production Line: Izinto | ||

| 1Isikhululo soBatching esizenzekelayo | 2Cement Silo | 3Screw Conveyor |

| 4Isikali sesamente | 5Isinyanzelo Umxubi | 6Ibhanti leConveyor |

| 7Umatshini weBhlokhi wekhonkrithi | 8ICandelo lokuxutywa kobuso | 9Iibhloko ezihambisa inkqubo |

| 10Stacker | 11Un-stacker | 12Inkqubo yokuhanjiswa kwePallet |

| 13ICuber ezenzekelayo | 14Phuma kwiConveyor | 15Igumbi lokunyanga |

| 16Isilayishi samavili | 17Phakamisa ifolokhwe | 18I-Fork Clamp |

Umxhubi onyanzelekileyo

Isikhululo sokudibanisa esizenzekelayo

Umatshini wokusonga

Iphalethi ijika

—— Isakhono seMveliso——

★Obunye ubukhulu bezitena obungakhankanywanga bunokubonelela ngemizobo yokubuza malunga nomthamo othile wemveliso.

| Umthamo wemveliso | ||||||

| UHercules M | Iibhodi zeMveliso: 1400 * 900 Indawo yoMveliso: 1300 * 850 Ukuphakama kwamatye: 40 ~ 500mm | |||||

| Proudct | Ubungakanani(mm) | Umxube wobuso | IiPC/umjikelo | Imijikelo/imiz | Imveliso/8h | Ukuvelisa cubic m/8h |

| Isitena esisemgangathweni | 240×115×53 | X | 60 | 4 | 115,200 | 169 |

| Ibhloko engenanto | 400*200*200 | X | 12 | 3.5 | 20,160 | 322 |

| Ibhloko engenanto | 390×190×190 | X | 12 | 3.5 | 20,160 | 284 |

| Isitena esiHollow | 240×115×90 | X | 30 | 3.5 | 50,400 | 125 |

| Paver | 225×112.5×60 | X | 30 | 4 | 57,600 | 87 |

| Paver | 200*100*60 | X | 42 | 4 | 80,640 | 97 |

| Paver | 200*100*60 | O | 42 | 3.5 | 70,560 | 85 |

| UHercules L | Iibhodi zeMveliso: 1400 * 1100 Indawo yoMveliso: 1300 * 1050 Ukuphakama kwamatye: 40 ~ 500mm | |||||

| Proudct | Ubungakanani(mm) | Umxube wobuso | IiPC/umjikelo | Imijikelo/imiz | Imveliso/8h | Ukuvelisa cubic m/8h |

| Isitena esisemgangathweni | 240×115×53 | X | 80 | 4 | 153,600 | 225 |

| Ibhloko engenanto | 400*200*200 | X | 15 | 3.5 | 25,200 | 403 |

| Ibhloko engenanto | 390×190×190 | X | 15 | 4 | 14,400 | 203 |

| Isitena esiHollow | 240×115×90 | X | 40 | 4 | 76,800 | 191 |

| Paver | 225×112.5×60 | X | 40 | 4 | 76,800 | 116 |

| Paver | 200*100*60 | X | 54 | 4 | 103,680 | 124 |

| Paver | 200*100*60 | O | 54 | 3.5 | 90,720 | 109 |

| Hercules XL | Iibhodi zeMveliso: 1400 * 1400 Indawo yeMveliso: 1300 * 1350 Ukuphakama kwamatye: 40 ~ 500mm | |||||

| Proudct | Ubungakanani(mm) | Umxube wobuso | IiPC/umjikelo | Imijikelo/imiz | Imveliso/8h | Ukuvelisa cubic m/8h |

| Isitena esisemgangathweni | 240×115×53 | X | 115 | 4 | 220,800 | 323 |

| Ibhloko engenanto | 400*200*200 | X | 18 | 3.5 | 30,240 | 484 |

| Ibhloko engenanto | 390×190×190 | X | 18 | 4 | 34,560 | 487 |

| Isitena esiHollow | 240×115×90 | X | 50 | 4 | 96,000 | 239 |

| Paver | 225×112.5×60 | X | 50 | 4 | 96,000 | 146 |

| Paver | 200*100*60 | X | 60 | 4 | 115,200 | 138 |

| Paver | 200*100*60 | O | 60 | 3.5 | 100,800 | 121 |

+86-13599204288

+86-13599204288