I-Palletizersisixhobo esizenzekelayo esisetyenziswa kakhulu kwimveliso yemizi-mveliso, ngakumbi ekupakishweni nasekunxibelelaniseni izinto. Ikakhulu isetyenziselwa ukupakisha ngokucocekileyo iimveliso eziveliswayo, ezinje ngengxowa, iibhokisi, kunye nezinto ezinkonkxiweyo, kwiipalethi, ukutyibilika, okanye abanye abathwali kulungiselelo oluthile kunye noomaleko ukwenza imilo yesitaki ezinzileyo, ukuququzelela imisebenzi elandelayo efana nokugcinwa, ukuthuthwa, ukulayisha kunye nokothula.

Ngokumalunga nolwakhiwo kunye neemodyuli ezisebenzayo, ai-palletizerngokuqhelekileyo ibandakanya iindawo eziphambili ezifana nenkqubo yokuhambisa, isixhobo sokubamba kunye nokubeka, inkqubo yokulawula, kunye nefreyimu. Inkqubo yokuhambisa inoxanduva lokuhambisa izinto ezifakwe kwi-palletized kwindawo yokusebenza ye-palletizer ngendlela ehlelekile, ukuqinisekisa ukuba izinto zinokufikelela ngokuchanekileyo kwindawo echongiweyo kunye nokulungiselela imisebenzi yokubamba elandelayo. Isixhobo sokubamba kunye nokubeka yinxalenye engundoqo yesigqeba se-palletizer. Inokusebenzisa iindlela ezahlukeneyo zokubamba, ezinje ngokubamba oomatshini, iikomityi zokufunxa, iikomityi zokufunxa, iindlela zokubambelela, njl.njl., ngokwemilo, ubungakanani kunye nobunzima bezinto ezahlukeneyo, ukubamba ngokuchanekileyo izinto kwaye uzibeke ngokutyibilikayo kwiindawo ezihambelanayo ngokwemowudi yokupakishwa kwangaphambili, ukuze uqonde ukupakishwa ngokucwangcisiweyo kwezinto. Inkqubo yokulawula "ingqondo" ye-palletizer. Ilawula ngokuchanekileyo yonke inkqubo ye-palletizing ngokusebenzisa iinkqubo ezakhelwe ngaphakathi kunye ne-algorithms, kubandakanywa nesantya sokuhamba kwenkqubo yokuhambisa, ulandelelwano lwesenzo sesixhobo sokubamba, indawo kunye neengqimba zokupakisha, njl., Ukuqinisekisa ukuzenzekelayo kunye nokusebenza kakuhle kwenkqubo yokudibanisa. Isakhelo sibonelela ngenkxaso ezinzileyo yecandelo ngalinye le-palletizer, ukuqinisekisa ukuzinza nokuthembeka kwezixhobo ngexesha lokusebenza.

Ngokumalunga nokuhamba komsebenzi, xa izinto eziza kufakwa kwi-palletized zingena kuluhlu olusebenzayo lwe-palletizer ngokusebenzisa inkqubo yokuhambisa, inkqubo yokulawula iya kuthumela imiyalelo yokubamba kunye nokubeka isixhobo ngokweeparamitha ezicwangcisiweyo kunye nesimo esisebenzayo ngoku. Isixhobo sokubamba sisebenza ngokukhawuleza, sibambe izinto ngokuchanekileyo, kwaye emva koko sihambisa izinto kwindawo echongiweyo ngaphezulu kwepalethi ngokwendlela yokupakisha ecwangcisiweyo kwaye sizibeke phantsi ngokucothayo ukugqiba ukupakishwa komgangatho omnye wezinto. Emva koko, inkqubo yokuhambisa iyaqhubeka nokuhambisa ibhetshi elandelayo yezinto, kwaye isixhobo sokubamba siphinda ezi zenzo zingasentla ukupakisha umaleko olandelayo. Lo mjikelo uyaqhubeka de ipallet ibekwe kwinani elimiselweyo lamaleya ukwenza istaki esipheleleyo. I-pallet egqityiweyo i-stacking iya kuhanjiswa ukusuka kwindawo yokusebenza ye-palletizer ngenkqubo yokuhambisa kwaye ingene kwindawo yokugcina impahla okanye ikhonkco lokuthutha.

IiPalletizerszineenzuzo ezininzi ezibalulekileyo. Okokuqala kukusebenza kakuhle. Inokuthi ngokuqhubekayo iqhube imisebenzi ye-palletizing ngesantya esikhawulezayo, esiphucula kakhulu ukusebenza kakuhle kwemveliso xa kuthelekiswa ne-palletizing ngesandla kwaye inokwanelisa iimfuno zokusebenza ngokufanelekileyo kumashishini amakhulu emveliso. Okwesibini kukuchaneka. Ngokusebenzisa inkqubo yokulawula echanekileyo kunye nesakhiwo somatshini, i-palletizer inokuqinisekisa ukuba into nganye ibekwe ngokuchanekileyo kwindawo echazwe kwangaphambili, kwaye imilo egciniweyo icocekile kwaye izinzile, ukuphepha iingxaki ezifana nokungahambi kakuhle kunye nokuthambekela okunokuthi kwenzeke kwi-palletizing manual, ehambelana nokhuseleko lwempahla yokugcina impahla kunye nokuthutha. Okwesithathu luzinzo. I-palletizer inokuqhuba ngokuzinzileyo ixesha elide kwaye ayichaphazeli lula kwizinto ezifana nokukhathala kwabasebenzi kunye neemvakalelo, ezinokuqinisekisa ukuqhubeka kunye nokuzinza kwenkqubo yokuvelisa kunye nokuphucula umgangatho wolawulo lwemveliso yamashishini. Ukongeza, malunga nokuqina kwabasebenzi kunye neendleko, ukusetyenziswa kwee-palletizers kunciphisa kakhulu ukuqina kwabasebenzi kunye nokunciphisa ukuxhomekeka kwamashishini emsebenzini. Ngokukodwa kwezinye iimeko zokuxinana kwephalethi ezinobunzima obuphezulu bokusebenza kunye neendawo zokusebenza ezirhabaxa (ezifana nobushushu obuphezulu, ubushushu obuphantsi, uthuli, ingxolo, njl. njl.), ayiqinisekisi impilo yabasebenzi kuphela kodwa inokunciphisa iindleko zabasebenzi ukuya kwinqanaba elithile.

Ngophuhliso oluqhubekayo lwetekhnoloji ye-automation ye-industrial, ii-palletizers nazo ziphuculwa ngokuqhubekayo kwaye ziphindaphindwa. Ii-palletizers zanamhlanje ziya zidibanisa ngakumbi itekhnoloji ephezulu efana nobukrelekrele bokwenziwa kunye nombono womatshini. Ukusetyenziswa kobuchwephesha bombono womatshini kwenza ukuba ii-palletizers ziqaphele imilo, umbala, indawo kunye nolunye ulwazi lwezinto ngexesha langempela ngokusebenzisa izinzwa ezibonakalayo ezifana neekhamera, ukuphucula ngakumbi ukuchaneka kokubamba nokubeka. Nokuba kukho ukutenxa kwisikhundla sezinto ngexesha lenkqubo yokuhambisa, inokulungiswa ngokuzenzekelayo kwaye ibuyekezwe. Itekhnoloji yobukrelekrele bokwenziwa inokwenza ukuba ii-palletizers zibe nobuchule obuthile bokufunda kunye nokwenza ngcono, zilungelelanise ngokuzenzekelayo isicwangciso sokupakisha ngokwemisebenzi eyahlukeneyo yemveliso kunye neempawu zento, kwaye ziqonde ngakumbi kunye nokusebenza ngokufanelekileyo kwe-palletizing.

Ngamafutshane, njengenye yezixhobo ezibalulekileyo zokuzenzekela kwimizi-mveliso, ii-palletizers zidlala indima engenakuthathelwa indawo kwimveliso yale mihla. Abaphuculi nje kuphela ukuphumelela kwemveliso kunye nomgangatho wemveliso yamashishini kodwa bakhuthaza ukuzenzekelayo kunye nophuhliso lwengqondo yenkqubo yonke yemveliso, ukubonelela ngenkxaso eqinile yokunciphisa iindleko zamashishini, ukunyuka okusebenzayo kunye nophuhliso oluzinzileyo.

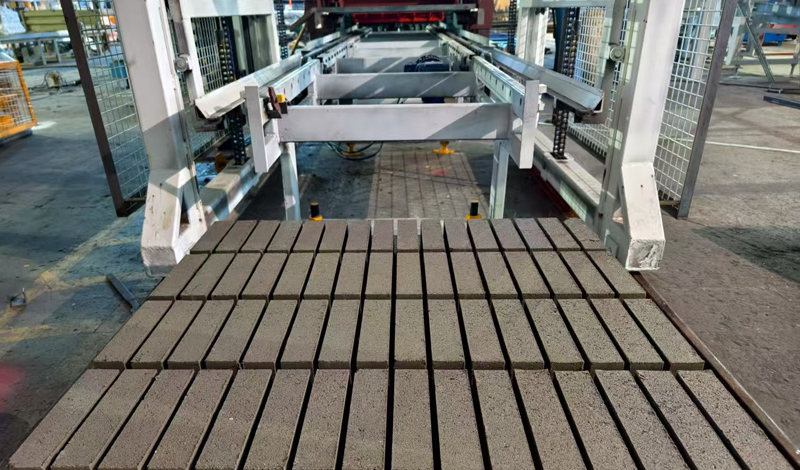

Umatshini osemfanekisweni ngui-palletizer.

I-palletizer sisixhobo esingundoqo esizenzekelayo kwimveliso yemizi-mveliso, ngakumbi kwiinkalo zokupakisha kunye nempahla. Ikakhulu isetyenziselwa ukupakisha ngobunono iimveliso ezahlukeneyo ezinje ngeengxowa, ezifakwe kwibhokisi, kunye nezinkonkxiweyo kubathwali abafana neepalethi ngokolandelelwano oluthile kunye noomaleko ukwenza imilo yesitaki ezinzileyo, ukuququzelela ukugcinwa kwempahla okulandelayo, ukuthuthwa, ukulayishwa kunye nokothula.

Ngokubhekiselele kwisakhiwo, i-palletizer iqulethe iinxalenye ezifana nenkqubo yokuhambisa, isixhobo sokubamba kunye nokubeka, inkqubo yokulawula, kunye nesakhelo. Inkqubo yokuhambisa ngokulandelelana ithumela izinto ukuba zifakwe kwi-pallet kwindawo yokusebenza; isixhobo sokubamba kunye nokubeka ingundoqo, enokuthi ibambe ngokuchanekileyo izinto ngokusebenzisa i-mechanical grippers, iikomityi zokufunxa i-vacuum, njl njl ngokwemilo yezinto kwaye uzibeke ngokwendlela yokuseta kwangaphambili; inkqubo yokulawula, njenge "ingqondo", ilawula ngokuchanekileyo isantya sokuhambisa, ukulandelelana ukubamba, indawo yokubeka kunye neengqimba ngokusebenzisa i-algorithms yeprogram ukuqinisekisa ukuzenzekelayo kunye nokusebenza kakuhle; isakhelo sibonelela ngenkxaso ezinzileyo kwicandelo ngalinye.

Ngethuba lokusebenza, izinto eziza kufakwa kwi-palletized zingena kuluhlu lokusebenza ngokusebenzisa inkqubo yokuhambisa, kwaye inkqubo yokulawula ithumela imiyalelo yokubamba kunye nokubeka isixhobo ngokweeparamitha kunye nesimo. Isixhobo sokubamba ngokukhawuleza sithatha izinto, sizihambise kwindlela ecwangcisiweyo ukuya kwindawo echongiweyo ngaphezu kwepalethi kwaye ngokucothayo uzibeke phantsi ukugqiba ukupakishwa komgangatho omnye. Emva koko, inkqubo yokuhambisa ithumela ibhetshi elandelayo yezinto, kwaye isixhobo sokubamba siphinda isenzo sokupakisha umaleko olandelayo. Umjikelo uyaqhubeka de i-pallet ifikelele kwinani elimiselweyo leengqimba ukwenza i-stack epheleleyo, kwaye emva koko ihanjiswa yinkqubo yokuhambisa ukungena kwindawo yokugcina impahla okanye ikhonkco lokuthutha.

IiPalletizerszineenzuzo ezibalulekileyo, ukusebenza kakuhle, ukuchaneka nokuzinza. Banokunciphisa ubunzima bokusebenza kwabasebenzi kunye neendleko zabasebenzi bamashishini, kwaye baqinisekise nokusebenza kwiindawo ezibuhlungu. Ngophuhliso lwe-automation ye-industrial automation, baphinde badibanise iteknoloji efana nobukrelekrele bokwenziwa kunye nombono womatshini ukuqhubela phambili ukuphucula ukuchaneka kunye nobukrelekrele, ukunceda amashishini ukunciphisa iindleko, ukwandisa ukusebenza kakuhle kunye nokufezekisa uphuhliso oluzinzileyo.

Ixesha lokuposa: Sep-05-2025

+86-13599204288

+86-13599204288